Nantong Hu Vegetable Tong Agricultural Development Co.

1. Usage:

The aluminum alloy series lift is designed by our company. The lifting platform has a beautiful appearance, small in size, lightweight, flexible and convenient operation; With two sets of upper and lower control lifting systems, the lifting is stable, safe and reliable. It is suitable for the repair, maintenance and cleaning of shopping malls, hotels, restaurants, interior decoration, exhibition arrangement, space lighting lines, pipelines, doors and windows, and is suitable for space operations in workshops with narrow areas or spaces. It is an ideal lifting machine and is well-received by the masses. Users welcome.

2. Notice:

2.1 Before using the lift, please read the instruction manual in detail so as to understand and master the operating procedure of the machine.

2.2 Operators should be familiar with and master the safety operating procedures in Article 4.

2.2.1 Expand (insert) outriggers:

In order to ensure personal safety and prevent accidents, this machine is equipped with four outriggers. Before use, the outriggers should be fully opened (insert the outriggers into the bushings on the chassis for no less than 200mm when using the plug-in outriggers) and rotate the screw handles on the top of the four outriggers to make the feet tightly support the ground.

2.2.2 Adjustment level:

Adjust the four lead screws so that the supporting feet are firmly supported on the ground and the equipment base must be kept level

2.2.3 Inspection before start-up

Before using the lift, please conduct a comprehensive inspection of the whole machine and lubricate the relevant parts.

(1) Check the chain system: Before starting the machine, carefully check the operation status of the chain system and adjust if necessary to make the chains evenly tightened, lock them with a spare nut, lubricate all parts of the chain and add a little 20 to the sprocket No. engine oil; people stand on the ground and press the up and down buttons. Check the operation of the machine, see if the chain is disengaged from the sprocket and see if the sprocket support plate is loose;

(2) Check the fuel tank: Check whether there is enough hydraulic oil in the fuel tank before starting the machine and replenish it in time if it is found to be insufficient.

(3) Check the power supply voltage level and check whether the action of each circuit breaker is sensitive:

(4) For double-column products, check whether the lifting and lowering of the guide rails on both sides are synchronized. If there is any asynchronous phenomenon, professional and technical personnel must be asked to adjust it before use.

(5) The above inspection items have been debugged and passed the factory and no adjustment is required before use. It can be used as a reference for future maintenance.

2.2.4 How operators work on the platform:

The operator should lift the railing from the front or enter the guardrail through a ladder and lock the guardrail at the correct position. The operator stands in the center and presses the up button to make the working platform rise slowly, stop at the desired position and start working. When working at heights, people should not shake or straddle the guardrail to avoid accidents. Press down button to go down. If there is a sudden power failure during work, the emergency manual lowering device can be activated to make the elevator land safely and return to the initial position.

2.2.5 Conditions:

(1) This product is suitable for use indoors or outdoors under windless (or light) conditions and cannot be used when the wind force is above level three;

(2) When the operating temperature is between -30°C and +40°C, use N46 high anti-wear hydraulic oil above 0°C and use N32 high anti-wear hydraulic oil below 0°C. Replace the hydraulic oil once a year;

(3) The machine should be used in an environment without strong vibration sources;

(4) This product should be used on a solid and flat ground. It is strictly forbidden to move during use, and it is strictly forbidden to use without supporting legs.

2.2.6 Fault and Maintenance:

Fault | Fault Cause Analysis | Elimination Method |

Loading Platform Cannot Rise Up | 1. Insufficient hydraulic oil 2. Leakage of oil inlet pipe 3. The guide rail is stuck 4. The workload is too heavy 5. The small guide wheels or sliders fall off or become loose 6. Oil spill 7.There is air in the hydraulic cylinder 8. The sealing ring is damaged 9.The pressure of the pressure regulating valve is small 10. There are foreign objects in the solenoid valve or one-way valve. | 1. Add enough hydraulic oil 2. Tighten the oil pipe joint 3. Check the guide rail 4. Check for overload 5. Check the guide rail 6. Eliminate oil leakage 7. Remove the air 8. Replace the sealing ring 9. Adjust the pressure valve 10. Clean the solenoid valve or check valve |

Loading Platform Climbing | 1. There is air in the oil system 2. The pressure of the pressure valve is too high | 1. How many times with no load during the full trip 2. Readjust the pressure valve |

Lifting Noise Loudly | 1. The oil system is abnormal 2. The load is too large 3. Whether the lifting guide rail is stuck | 1. Check the oil system 2. Lighten the load 3. Check the guide rail and eliminate |

2.3 Maintenance: When the working time exceeds 200 hours or every one year, the oil tank should be cleaned and the hydraulic oil replaced; after two years, it should be overhauled by professionals; after five years, it should be returned to the factory for appraisal and maintenance.

3. Safety operating procedures

3.1 Aluminum alloy series lifts, the rated load includes the total weight of people and items carried and do not overload;

3.2 The level must be adjusted before use, otherwise it cannot be used;

3.3 The lift is not allowed to move or adjust the base during work;

3.4 It is not allowed to climb or stand on the guardrail of the manned platform;

3.5 It should be used on a solid and flat ground and it is never allowed to be used on a temporary stand, truck (truck, truck, uncovered car, etc.), bed or protruding plane;

3.6 When the lift is working, no load is allowed to touch the side to prevent accidents;

3.7 If the ground is soft under the feet, a firm sleeper should be placed and adjusted securely;

3.8 When the lift is working, people are not allowed to stand under the manned frame, and it is not allowed to use ladders to increase height in the manned frame. There must be no obstacles such as erected wires and protruding branches within the working range of the lift;

3.9 The aluminum alloy lift cannot be tilted. When used close to a high wall, the lifting height shall not be greater than the height of the high wall;

3.10 Before using the garden lift, the outriggers must be loosened first, and after use, they should be put away and fastened before transportation;

3.11 When the courtyard lift is running on the road, the maximum speed shall not exceed 40 km/h;

3.12 Before the lift with a tilting frame is laid down or erected, the positioning pin must be inserted into the hole on the wheel, and the support rod must be connected before being laid down or erected. Care must be taken to prevent accidents.

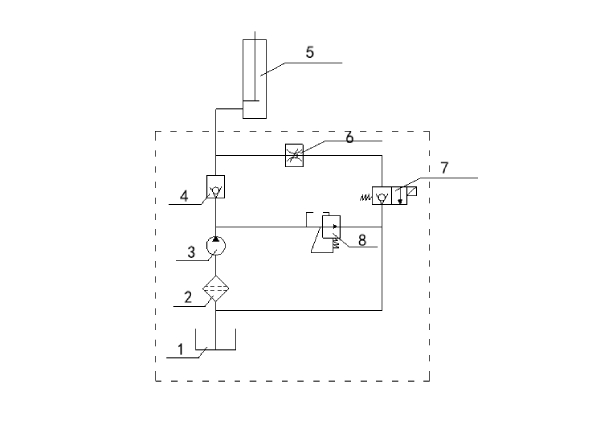

4. Hydraulic Schematic Diagram

1 | Fuel Tank |

2 | Oil Filter |

3 | Oil Pump |

4 | Check Valve |

5 | Oil Cylinder |

6 | Throttle Valve |

7 | The Electromagnetic Valve |

8 | Relief Valve |

5.Photo: